¶ Maintenance

The simulator will need a bit of maintenance occasionally, below you can see a list of the things you need to check for. As for every product that can move bolts and nuts might come loose over time and you need to check the overall state of the simulator.

- Checking bolts and nuts every few weeks to ensure nothing is getting loose.

- Clear the dust filters on the three fans on top of the cover.

- Listen for any abnormal noises, if encountered please follow the below instruction on how to grease the ball joints inside the simulator.

¶ Noises

While using the simulator you might hear different noises due to the mechanical components. Below you can see a list of common noises and their cause.

-

Squeaking - Common noise from the seat or seat slider. Lubrication or tightening bolts will fix it.

-

High pitched noise - usually comes from the ball head joints. Use the below guide to lubricate them.

-

Grinding noise - usually comes from the gearboxes on new units. The noise will go away after some use.

-

Rattling noise - Comes from the ball head joints when the simulator is not in balance. Balancing the simulator will put weight on all joints and remove the noise.

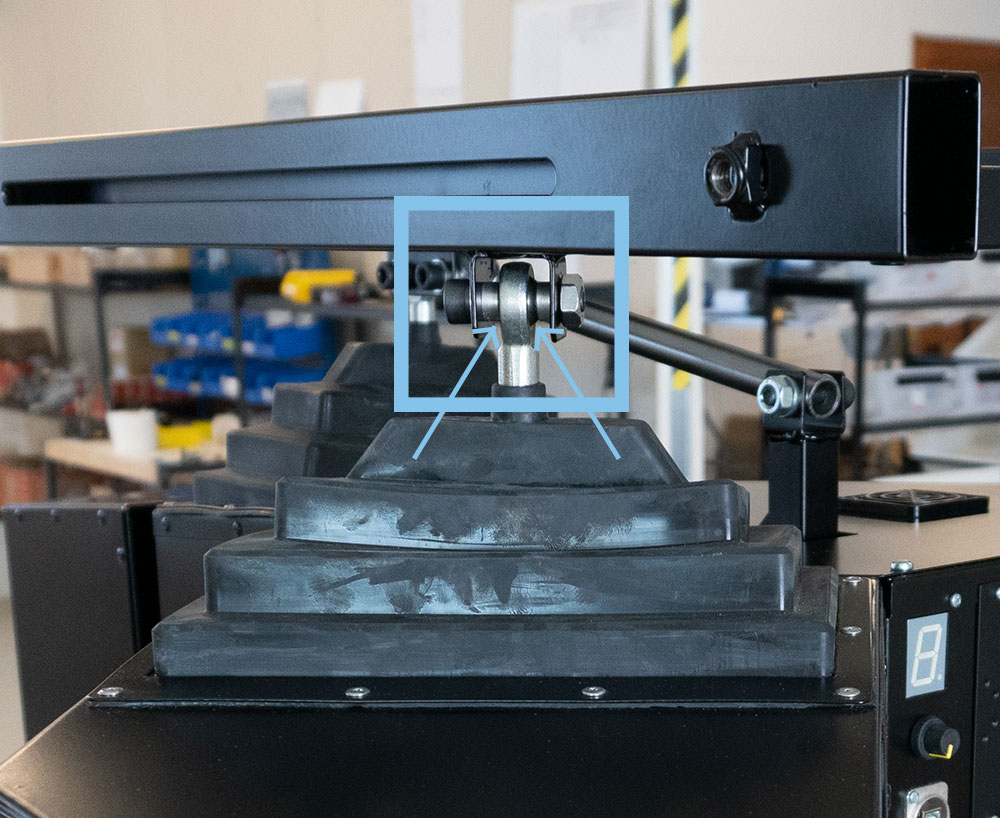

¶ Lubricating Joints to Avoid Noises

After some use you can encounter a high-pitched noise coming from behind the cover. The noise can be hard to locate but is due to the ball joints used to rise and lower the upper frame. A quick solution is to use WD40 or similar and tilt the simulator slightly. From below you can see the joints and you are able to lubricate them. It might take a few tries to be sufficiently lubricated.

Step 1: turn the simulator off and push down the frame so the motors is at their lowest position. Lubricate the joints shown on the picture. They are usually not the ones causing the squeaking, we will have to look below the simulator to find the cause.

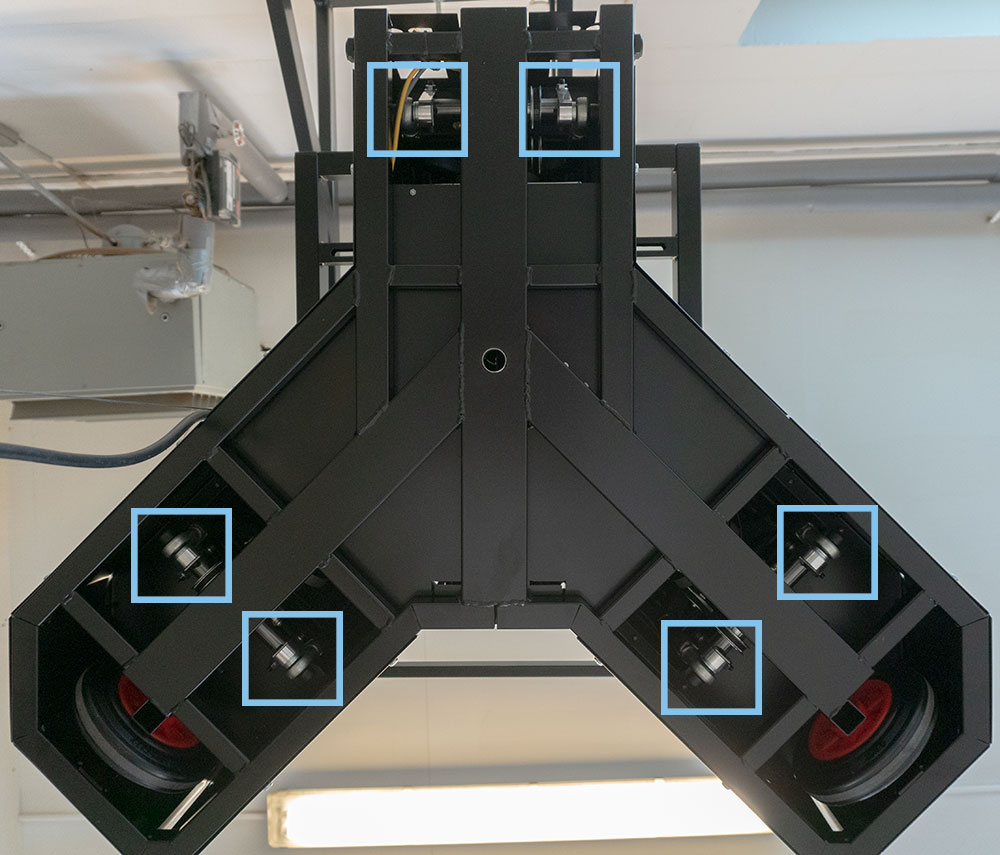

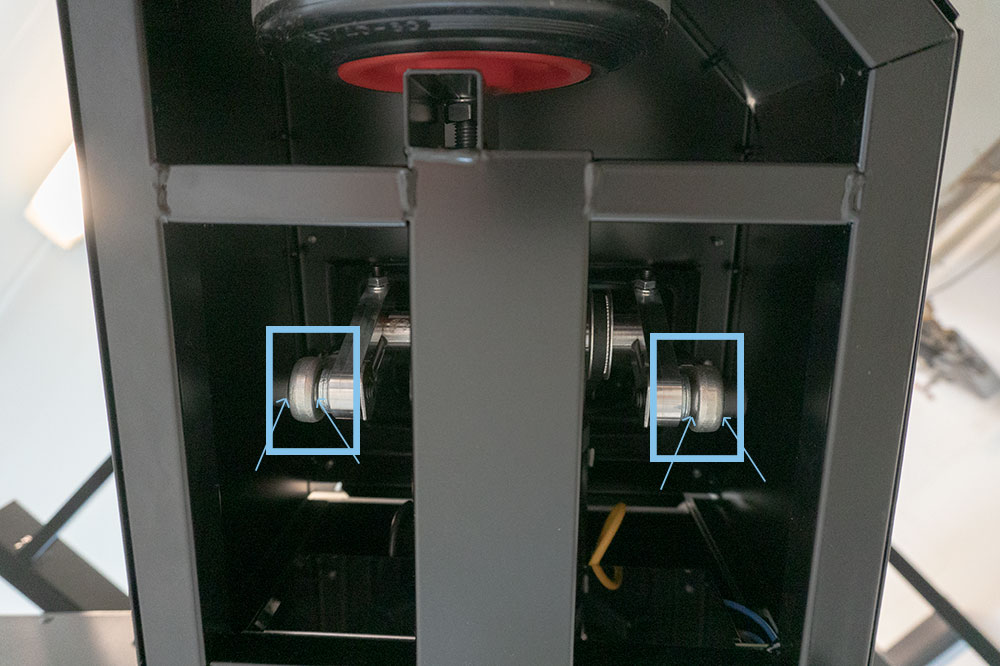

Step 2: By tilting the simulator (Two persons preferred for this task) you will get a look beneath the simulator. Make sure there is no power to the system and you can securely lie beneath the simulator to have a good look.

Step 3: Locate the 2x3 ball joints and lubricate them with silicone spray or similar (Not WD40). Give them just enough to not spilling anything. You might have to repeat one or two times after using it for a few minutes, usually once is enough.

¶ Repair

The simulator should under no circumstances be repaired by unauthorized personnel without consulting us first. Failing to obey this can cause injury to equipment and personnel. The cover of the machine is not made to be taken off and no maintenance beneath it is necessary besides lubrication.